FD800

FD800 Series Engineering Drive Frequency Inverter

The FD800 Series Drive Frequency Converter is a kind of electric drive product for high end industry. It has a complete control system. High speed DSP is used as the core of the main control system, and the control arithmetic is digital, so it has good motor speed and torque control capability.

BASIC INFO

Rated input voltage (V)

380~440VAC ; 520~690VAC

Rated input frequency (Hz)

50Hz/60Hz,Range:±5%

Output power (kW)

0~3200KW

Output frequency (Hz)

0~400Hz

Lead time

25~60 days, depends on order quantities

OEM/ODM

Acceptable

Features

Description

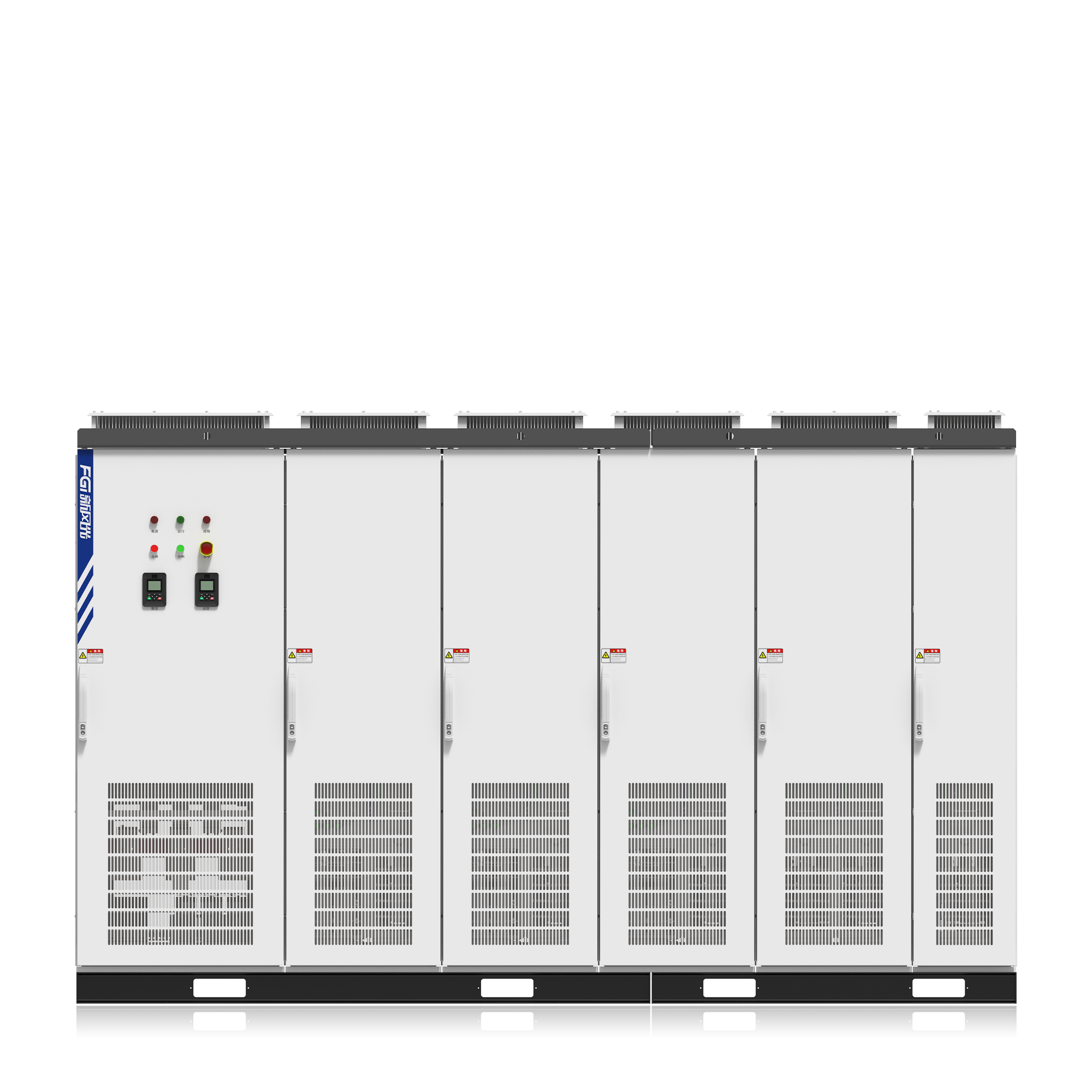

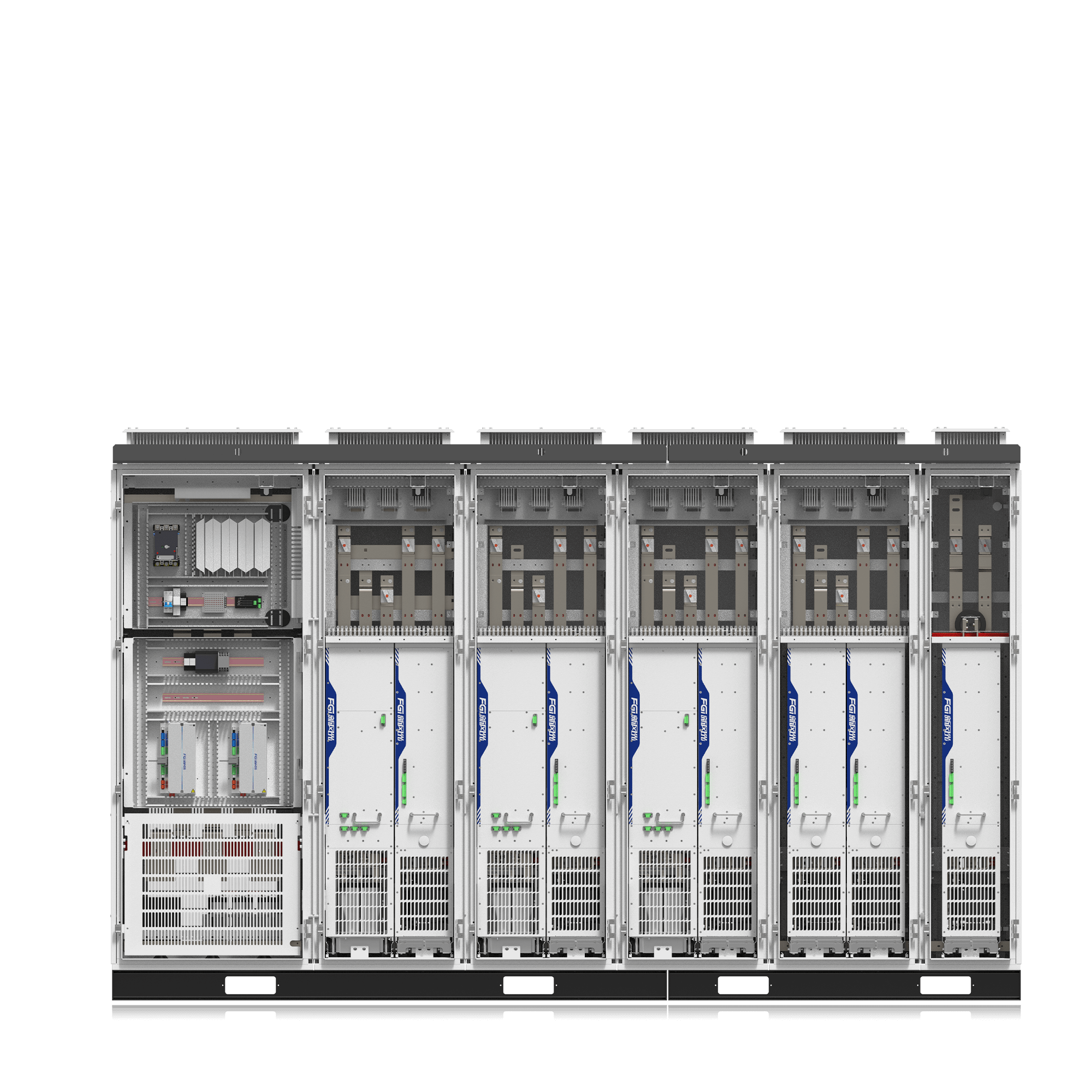

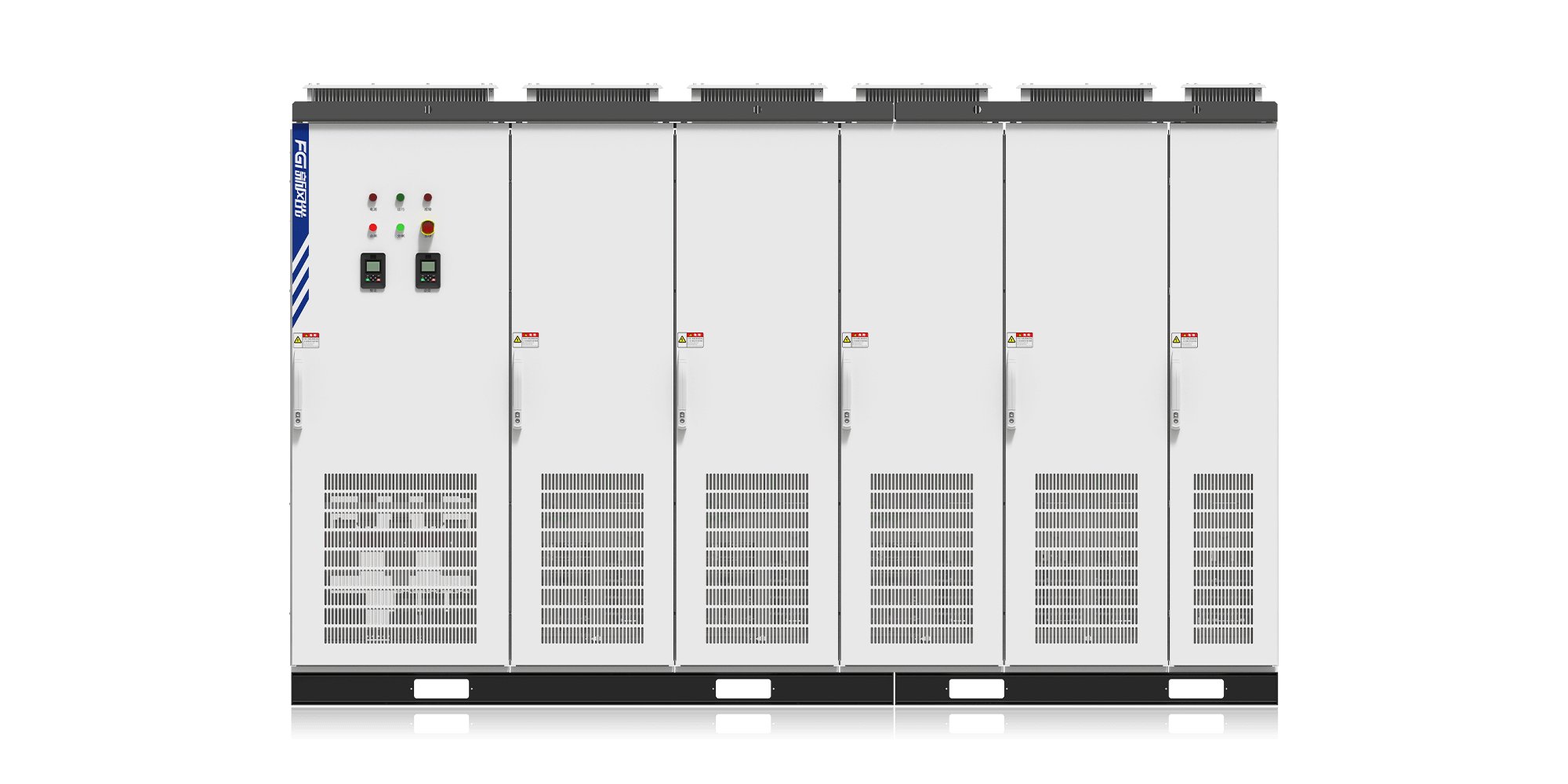

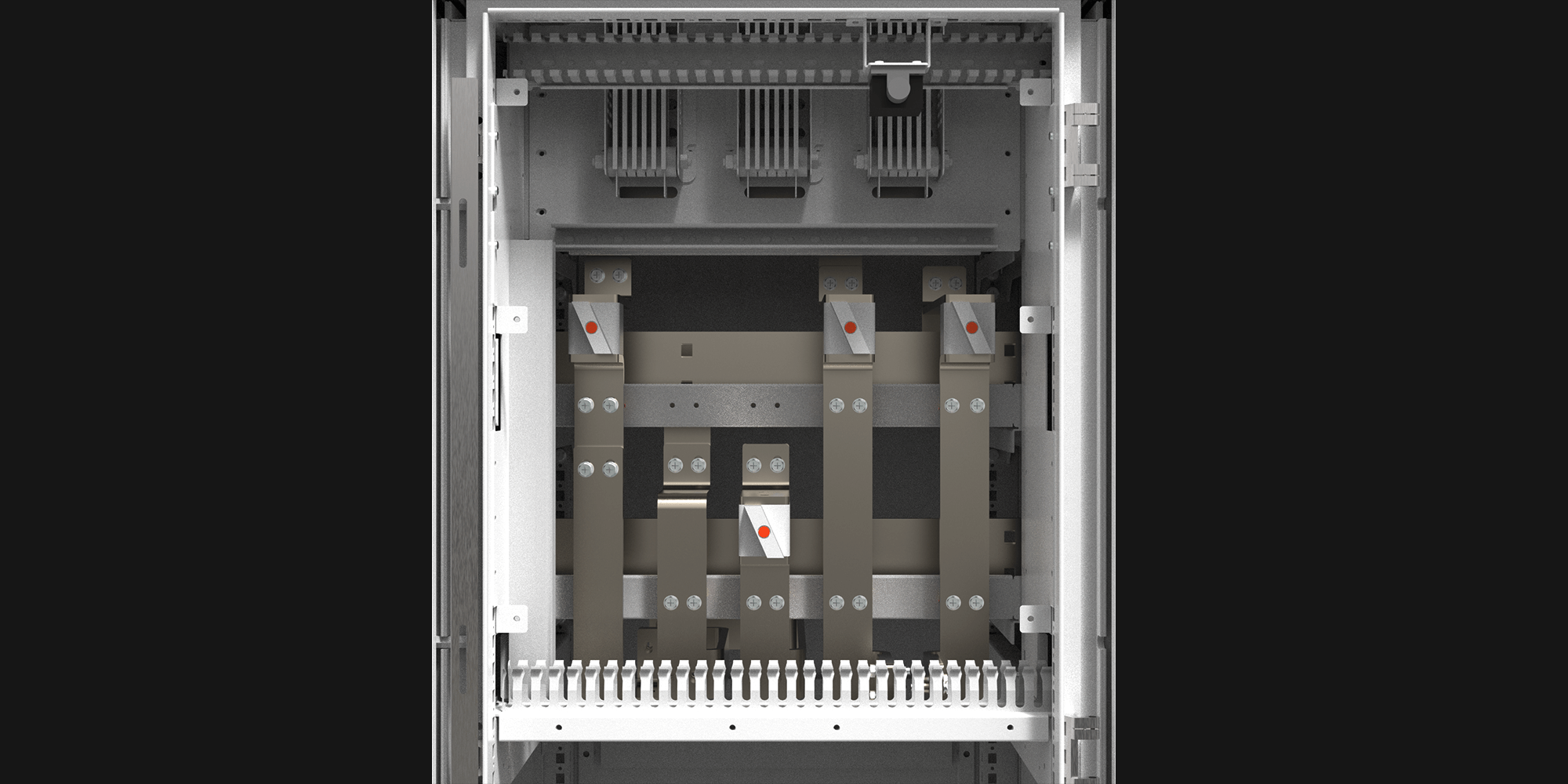

Cabinet products:

- Standard two quadrantcabinet machine:400V 200-3000kW(customizable for 12000kW) / 690V 200-3300kw(customizable for 13000kW)

- Simple four quadrantcabinet machine: 400V 200-3000kW(customizable for 12000kW) / 690V 200-3300kW(customizable for 13000kW)

- Standard four quadrant cabinet machine: 400V 200-3000kW(customizable for 12000kW / 690V 200-3300kW(customizable for 13000kW)

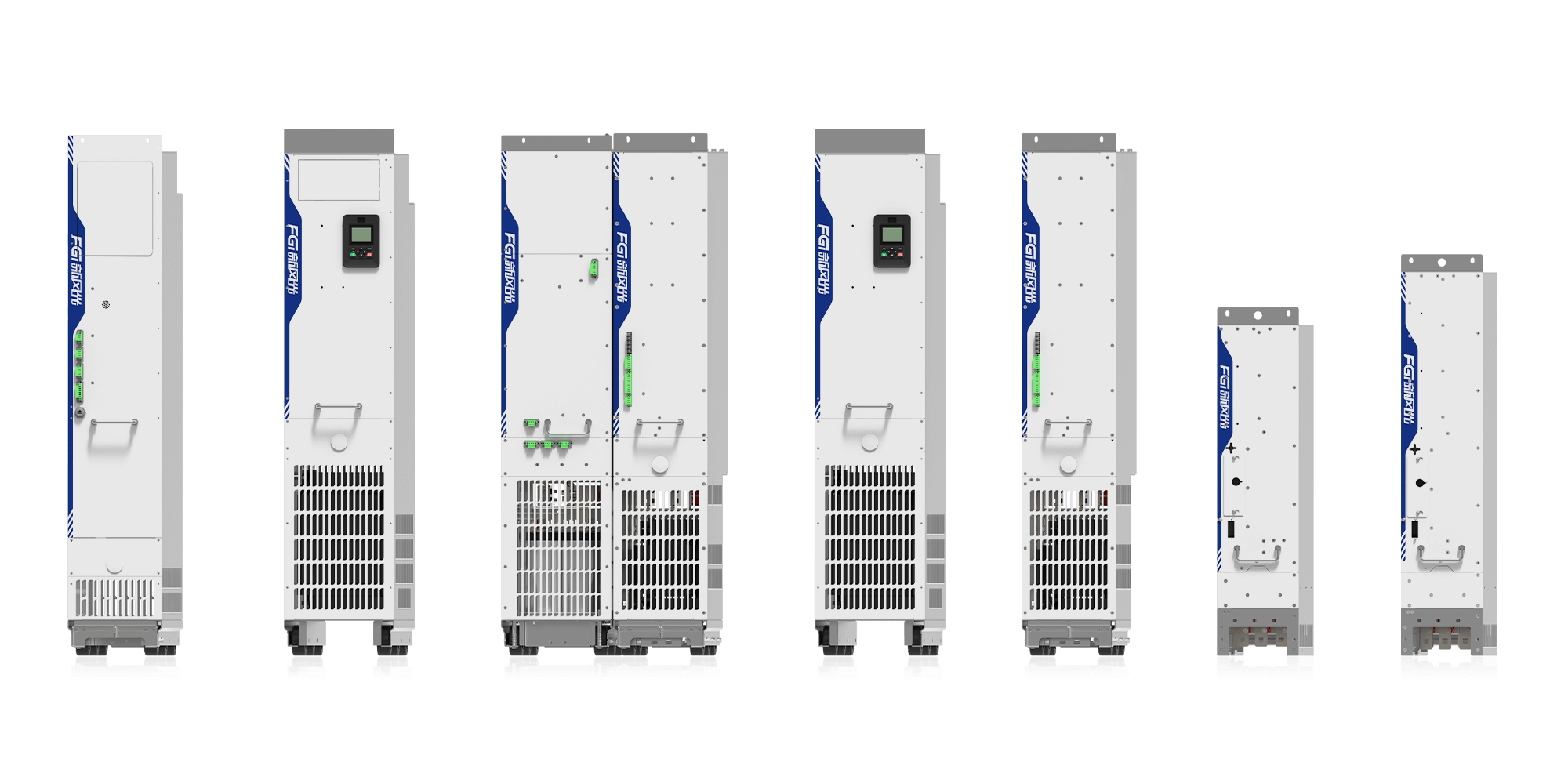

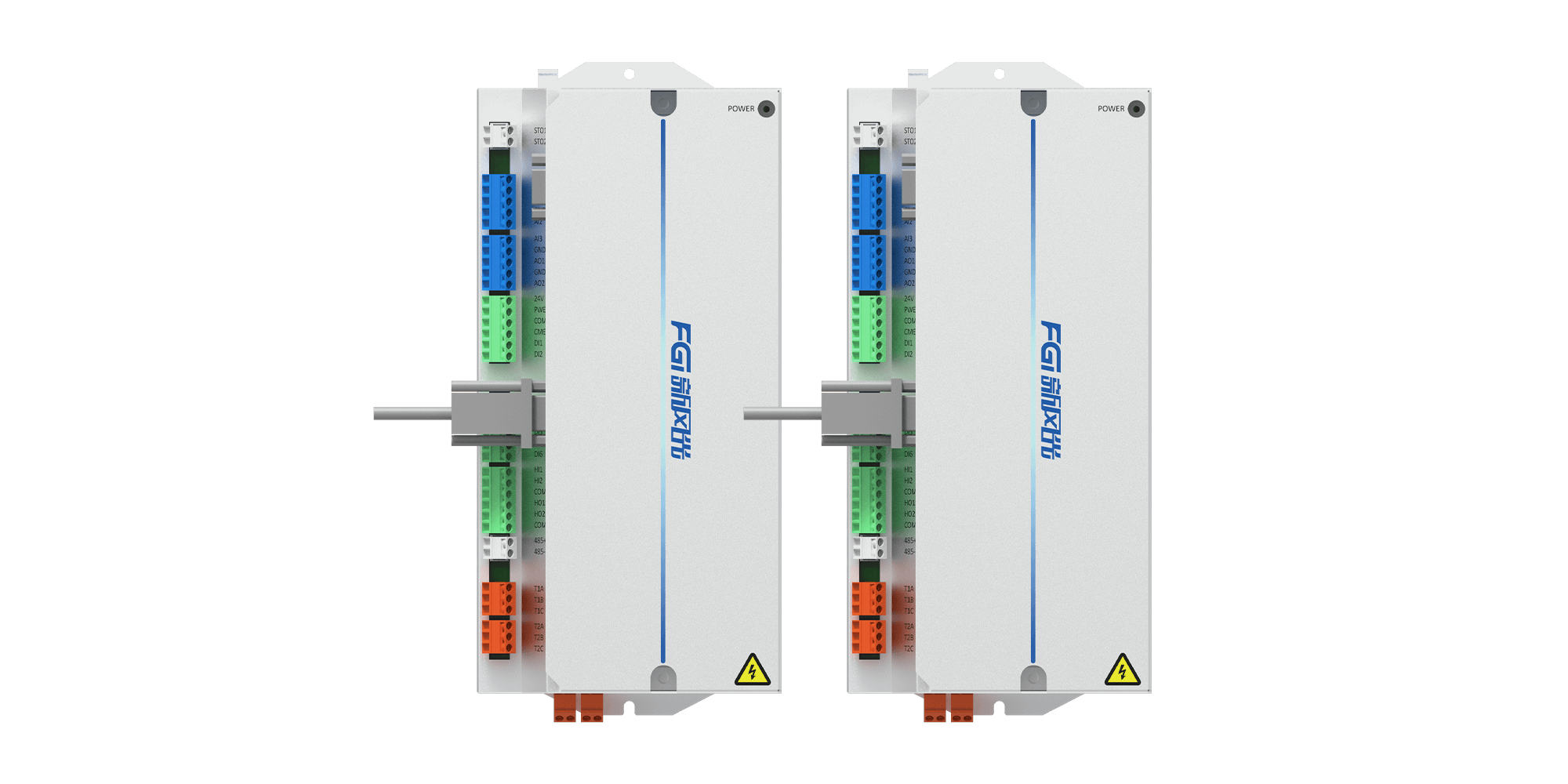

Unit product:

- Diode rectifier unit:400V 200-1000kW / 690v 200-1200kW / 690V 200-710k

- SvnchronousRectification unit:400V 200-630kW

- WAfe rectifier unit:400V 200-500kW / 690V 200-560kW

- Inverter unit:400V 37-500kW / 690V 37-560kW

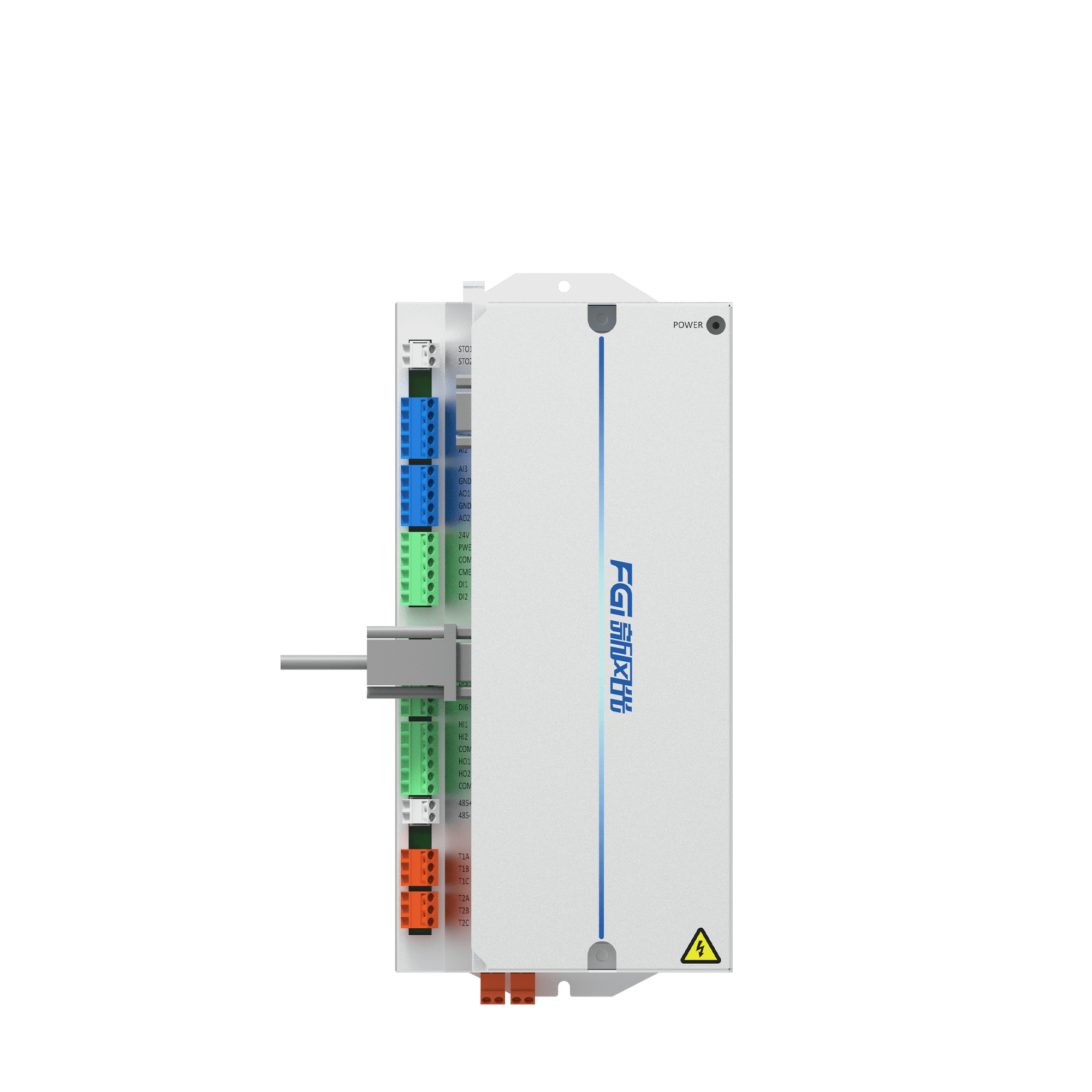

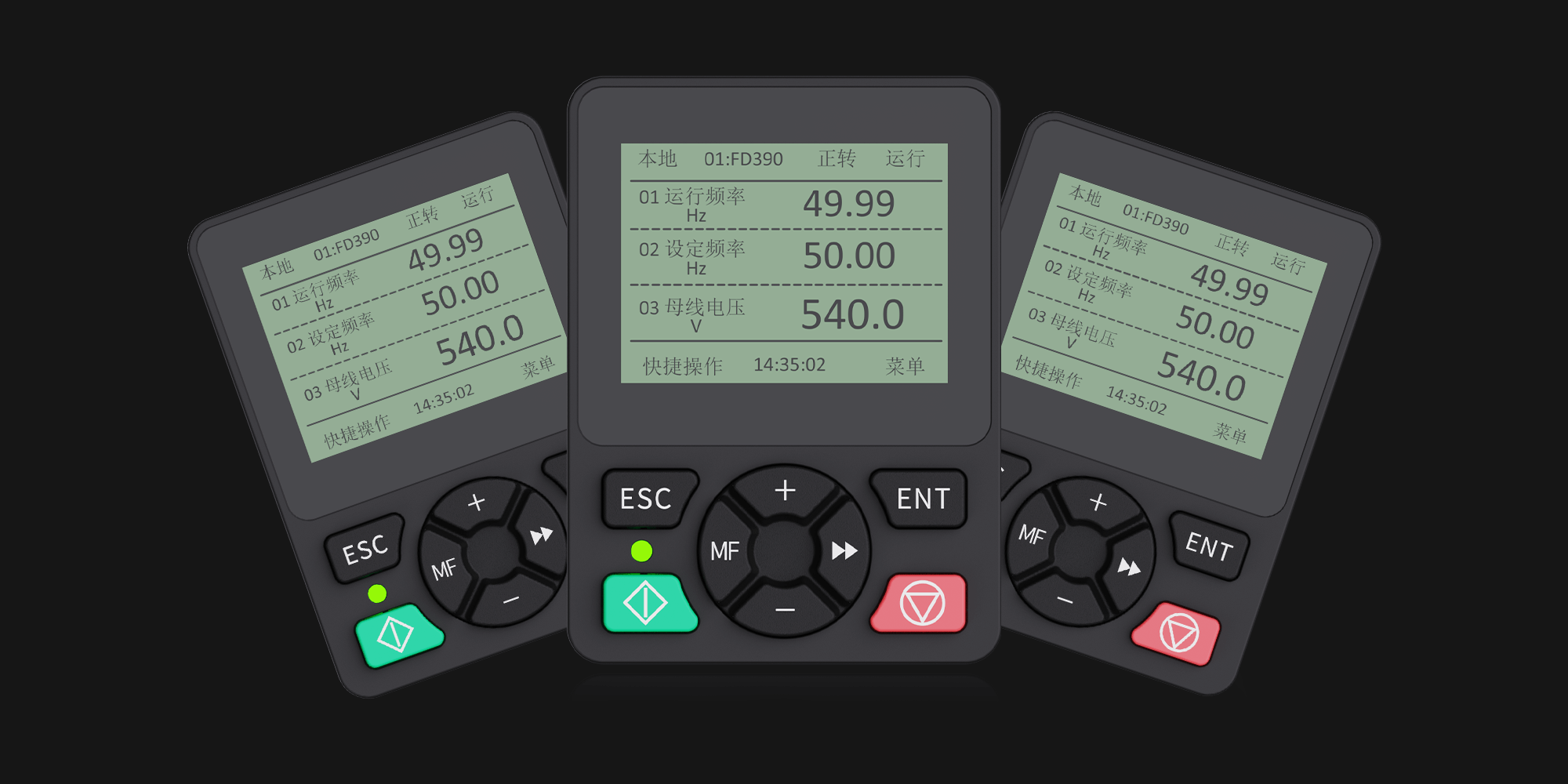

Multifunction keyboard:

- LCD display screen

- Supports multiple languages

- 8-line text display

- Parameter copying & recovery

Parameters

Input voltage

3AC 380V (-15%) ~ 440V (+10%)

3AC 525V (-15%) ~ 690V (+10%)

Input frequency (Hz)

47–63Hz

Rated input efficiency

>98.5%

Output frequency

0~Input voltage

Output power (kW)

55kW~13000kW

Output frequency (Hz)

0–500Hz

Control mode

Space voltage vector control, sensorless vector control (SVC), and vector control with sensor feedback (FVC)

Operation mode

Two-quadrants control, Four-quadrants control (AFE)

Speed control predcision

±0.5% (V/f)

±0.2% (SVC)

Harmonic level of AFE type of FD800 (current harmonics at grid side)

<5%@50% load ;<4%@80% load ;<4%@100% load ;

Motor type

Asynchronous motor (AM)

Permanent magnetic synchronous motor (SM)

Speed regulation ratio

For AM1: 1:200 (SVC); for SM1, 1:20 (SVC); 1:1000 (FVC)

Speed control precision

± 0.2% (SVC); ± 0.02% (FVC)

Speed fluctuation

± 0.3% (SVC)

Torque response

< 20ms (SVC); < 10ms (FVC)

Torque control precision

10% (SVC); 5% (FVC)

Starting torque

For AMs: 0.25Hz/150% (SVC)

For SMs: 2.5Hz/150% (SVC)

0Hz/200% (FVC)

Overload capacity

150% for 1 min (every 5 mins); 180% for 10s; 200% for 1s

Frequency setting method

Settings can be implemented through digital, analog, pulse frequency, multi-step speed running, simple PLC, PID communication, communication and so on.

Settings can be combined and the setting channels can be switched.

Communication

Modbus (standard)

Optional: CAN, CANOpen, Profibus, Profinet, EtherCAT, Ethernet, etc.

Automatic voltage regulation

The output voltage can be kept constant although the grid voltage changes.

Fault protection

More than 30 protection functions, such as protection against overcurrent, overvoltage, undervoltage, overtemperature, phase loss, and overload

Speed tracking restart

RUsed to implement impact-free smooth startup for rotating motors

Terminal analog input resolution

No more than 20mV

Terminal digital input resolution

No more than 2ms

Analog input

3 channels: AI1, AI2, AI3: 0~10V/0(4) ~20mA

Analog output

2 channels; AO1: 0~10V/0(4)~20mA

Digital input

6 channels regular input; max. frequency: 1kHz; internal impedance: 3.3kΩ

2 channels high-speed input; 0~100kHz

Digital output

2 high-speed pulse output; 0~100kHz

Relay output

4 programmable relay outputs

Contact capacity: 3A/AC250V, 1A/DC30V

Extended interfaces

3 extended interfaces: SLOT1, SLOT2, and SLOT3

Supporting PG cards, communication cards, I/O cards and so on

Mounting method

Wall mounting, floor mounting, and flange mounting

Temperature of running environment

-10 – +50°C; derating is required if the ambient temperature exceeds 40°C

Pollution degree

Degree 2

Vibration

The max. amplitude of vibration should not exceed 5.9m/s2 (0.6g)

Cooling method

Forced air cooling / Water cooling

Protection level

IP20 (standard)

IP21 (optional)

IP54 (optional)

EMC filter

The transmission of the AC drive meets the IEC/EN 61800-3 C3 requirements.

When optional filters are connected externally, the transmission of the AC drive can meet the IEC/EN 61800-3 C2 requirements.

Note: Comply with the EMC requirements and the technical requirements for the motors and motor cables in the appendix in the manual.

APPLICAITON